TIG welding power supplies are usually Stick welding power supplies. Tungsten is the item that gives us TIG welding because, without it, we wouldnt haveTIG welding. Let's start by defining inverter technology. However, its also gratifying, and once you get the hang of it, youll be creating beautiful metal workpieces in no time at all. Second take a air cooled TIG torch and hook it up to the stinger or electrode holder. It is very difficult to weld standing with a foot pedal remote start. I strongly advise against that method! TIG welding is mostly used for critical weld joints, welding metals other than common steel, and where precise, small welds are needed. The second option is remote start. Press the switch , you get and arc. All youll need is an air-cooled TIG torch and an extra bottle of Argon. Welding aluminum always requires a high frequency start from either a high production button or a foot pedal operated TIG torch. To address some of the questions I frequently got asked or was wondering myself during my job, I started this blog. When it comes to open root welds on copper nickel there is a different technique used.  The only differences between a flat, horizontal, vertical and an overhead weld is how you mentally approach the task. This allows you to change the percentage of time the current is in the EN (Electrode Negative) mode and the EP (Electrode Positive) mode. Youll more likely use then when welding aluminum or magnesium. tig dc ac sherman welder welding aluminium machine amp Wrong!

The only differences between a flat, horizontal, vertical and an overhead weld is how you mentally approach the task. This allows you to change the percentage of time the current is in the EN (Electrode Negative) mode and the EP (Electrode Positive) mode. Youll more likely use then when welding aluminum or magnesium. tig dc ac sherman welder welding aluminium machine amp Wrong!  Below weve included a list that has guidelines for your machine set-up when welding mild steel. Some other inverter welders may have more than a dozen dials to adjust, but the Miller machines have one dial, plus neat vertical columns of settings, with a single touch-pad button for each column that cycles through the options, making it easy to set and understand. tig welder welding machine display digital The way most TIG welds are done is with a side to side motion of the TIG torch. Try a new filler rod. With weathered or coated aluminum, a lower percentage of EN, which provides more cleaning action, may work better. 1% Thoriated Tungsten comes with a yellow colored tip and has an AWS classification of EWTh-1 on the package. If you want to comprehend how DC works with mild steel, think about the way water moves. Youll wind up with an excellent torch thats very efficient if you go this route. Its all about friction. TIG welding wires come in many sizes and these are the more common diameters: Joint set-up is extremely critical when it comes to TIG welding. There are three possible settings here. In the U.S., 120- and 240V current is most common, and it is delivered at 60 cycles-per-second, or Hertz (Hz). Many companies may use alternative names when placing ads in the classifieds.

Below weve included a list that has guidelines for your machine set-up when welding mild steel. Some other inverter welders may have more than a dozen dials to adjust, but the Miller machines have one dial, plus neat vertical columns of settings, with a single touch-pad button for each column that cycles through the options, making it easy to set and understand. tig welder welding machine display digital The way most TIG welds are done is with a side to side motion of the TIG torch. Try a new filler rod. With weathered or coated aluminum, a lower percentage of EN, which provides more cleaning action, may work better. 1% Thoriated Tungsten comes with a yellow colored tip and has an AWS classification of EWTh-1 on the package. If you want to comprehend how DC works with mild steel, think about the way water moves. Youll wind up with an excellent torch thats very efficient if you go this route. Its all about friction. TIG welding wires come in many sizes and these are the more common diameters: Joint set-up is extremely critical when it comes to TIG welding. There are three possible settings here. In the U.S., 120- and 240V current is most common, and it is delivered at 60 cycles-per-second, or Hertz (Hz). Many companies may use alternative names when placing ads in the classifieds.  or when you need to weld near threads and you dont want to arc off and damage the threads. If you are in a sealed room and you have a bottle of Argon leaking, it will fill the room from bottom up, just like water would. As long as your amperage is set properly and you see the weld puddle wash into the sides of the weld you should be fine. The filler metal is just a wire that is dipped by hand into the arc and melted. Just looking to weld mild steel, not sure which process to use yet?

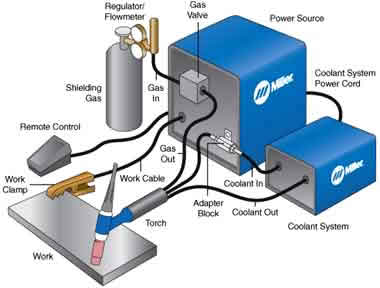

or when you need to weld near threads and you dont want to arc off and damage the threads. If you are in a sealed room and you have a bottle of Argon leaking, it will fill the room from bottom up, just like water would. As long as your amperage is set properly and you see the weld puddle wash into the sides of the weld you should be fine. The filler metal is just a wire that is dipped by hand into the arc and melted. Just looking to weld mild steel, not sure which process to use yet?  Raise gas flow rate. Aluminum just has a shiny puddle that does not glow. Too small a percentage (less than 60 percent) can degrade the point on the tip of the tungsten electrode. If you put in one bead and then need to put in a second pass you also need to clean that area again before welding. If a water cooled TIG torch is being used then a water cooler will be needed. After the shape is obtained turn the power supply back to A/C.

Raise gas flow rate. Aluminum just has a shiny puddle that does not glow. Too small a percentage (less than 60 percent) can degrade the point on the tip of the tungsten electrode. If you put in one bead and then need to put in a second pass you also need to clean that area again before welding. If a water cooled TIG torch is being used then a water cooler will be needed. After the shape is obtained turn the power supply back to A/C.

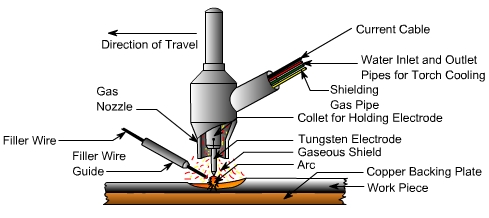

Pre-flowthe length of time the torch gas flows between the time you press the switch or remote foot pedal, and when you actually get an arc. D/C Current operates much like a car battery does, and can only flow one way. Thoriated Tungsten is used for welding most metals besides aluminum and magnesium. Oh yeah, don't wear gloves while doing this! That means youll have plenty of Tungsten to use while welding your mild steel.  Some of the common causes of weld porosity are: Tungsten deteriorating or an unstable arc is typically due to the following causes: This site is broken down into five major sections based on the natural progression of career minded welders who plans to make their living from welding. The next column is for Process. When comparing freehand welding to walking the cup there is a huge difference in weld quality and appearance! Unlike water you cannot see or smell it. After that, youll need to follow the steps below: Once youve completed these steps, youve successfully converted your stick welder into a TIG welder. Part of learning the process of TIG welding means youll need to learn how to set up a TIG welder for mild steel. The water cooler is what cools the TIG torch. Then the welder presses a foot pedal and the TIG torches tungsten electrode starts an arc. When using a grinding wheel it is best to use a fine grit wheel that is only to be used for sharpening Tungsten electrodes.

Some of the common causes of weld porosity are: Tungsten deteriorating or an unstable arc is typically due to the following causes: This site is broken down into five major sections based on the natural progression of career minded welders who plans to make their living from welding. The next column is for Process. When comparing freehand welding to walking the cup there is a huge difference in weld quality and appearance! Unlike water you cannot see or smell it. After that, youll need to follow the steps below: Once youve completed these steps, youve successfully converted your stick welder into a TIG welder. Part of learning the process of TIG welding means youll need to learn how to set up a TIG welder for mild steel. The water cooler is what cools the TIG torch. Then the welder presses a foot pedal and the TIG torches tungsten electrode starts an arc. When using a grinding wheel it is best to use a fine grit wheel that is only to be used for sharpening Tungsten electrodes.

Stainless Steel to Low Alloy or Carbon Steel. The handle will start feeling hot to the touch after ten to fifteen minutes of welding, meaning youll have to stop and take breaks from time to time if you opt for an air-cooled TIG torch for mild steel. As with all electrodes there are choices in electrode diameters. Some of the common problems include: Weld Porosity can be caused by many factors. The joint must be absolutely free of anything except clean stainless steel. The bottom selection is for Stick welding, either AC or DC. The down side is the air cooled TIG torch is it heats up quite a bit and much of the heat the arc produces is wasted. Youll also find Tungsten used in things like rocket engines, heaters, andlight bulbs. 200a 208p So, you can see by this comparison why Tungsten works so well on steelwhen welding. Typically TIG welding wire comes in 36" lengths. So, you wont wind up using your Tungsten up as quickly. We'll take a detailed look at these settings shortly.  The common metals added to Tungsten are Cerium, Lanthanum, and Zirconium. Cadillac tig welders but the problem is the darn thing is as big as a duty cart. What changes is there are very small percentages of other metals added to help create the desired arc characteristics. Weld metal is not cleaned properly. Now that you understand your options in TIG torches, well cover the TIG welding machine set-up for welding mild steel. This process is slow but when done right it produces the highest quality weld! For reasonably clean metal, 75 percent EN should be a good place to start.

The common metals added to Tungsten are Cerium, Lanthanum, and Zirconium. Cadillac tig welders but the problem is the darn thing is as big as a duty cart. What changes is there are very small percentages of other metals added to help create the desired arc characteristics. Weld metal is not cleaned properly. Now that you understand your options in TIG torches, well cover the TIG welding machine set-up for welding mild steel. This process is slow but when done right it produces the highest quality weld! For reasonably clean metal, 75 percent EN should be a good place to start.  To avoid this it is best to hit the joint with a sanding disk or a file. Amperage settings vary depending on the type and thickness of the metal to be welded. Basically the side is gaining water is the side with the most friction. After that, you will have formed one piece of metal. Change polarity or voltage type. berk tig welder 200a gasless tig welder settings It is just like a Jacobs's ladder used in science experiments. You just insert the probe and it takes a reading of the atmosphere. This eliminates the need to physical strike an arc. I have found that the default settings work very well for me, but you can experiment with these settings if you want. Most of it comes down to a positive mind set and practicing! So, D/C power works with heat in welding the same way it does when you move water from a pitcher to a glass. TIG torch connection is loose. That also includes the weld area. This is why most manufacturers have been switching to inverters for the last several years. The anodized pipe has a coating that makes it very difficult to weld. This allows the electrode to concentrate the arc temperature onto the metal. Furthermore, youll also discover that TIG welding also uses twopolarity types, much like Stick welding, when it comes to utilizing direct current. Ultimately this process creates a single piece of metal. Since youll want to avoid doing this, make sure you hit the joint with a sanding disk or file tokeep it clean. In welding, instead of focusing on who is gaining water, we focus on the side of the heat thats most concentrated when working with sheet metal. You just set the amperage to a point that you are comfortable with how fast it melts the metal your welding. Just like any other welding process the filler wire for TIG welding has a designation coding system. The center column is for the Pulser, which is typically only used for DC welding. Welderskills Video shows Stick Welding 1/4" carbon steel bumper 7014 1/8", Welderskills Video shows Mig Welding Aluminum 1/2" thick vertical uphill settings technique, Welderskills Video shows 2 inch Schedule 80 6g pipe test 7018 3/32" cap, Home | Contact | About Me | Privacy Policy |Site Map|Forum |Store, Copyright 2007-2020 WeldingTipsandTricks.com, See Hundreds of Quick 30 second videos showing TIG welder settings for all types of Welds, Stick Welding 1/4" carbon steel bumper 7014 1/8", Mig Welding Aluminum 1/2" thick vertical uphill settings technique, 2 inch Schedule 80 6g pipe test 7018 3/32" cap. Once the TIG torch is activated the high frequency start feature will can literally create an arc across a one inch gap between the TIG torch and the metal! The second step is to spot or bump weld around the same weld without adding filler wire. I learned this very early on when I started to weld. That is only true if you use too much heat and in that case the metal will turn very dark. tig welder With the frequency settings, you can use frequency ranges and other pulses of electricity to modify the arc, so you get what you want. Clean with grinder or wire brush. Once you get the proper size ball at the end of the electrode, stop the arc. Basically any place that requires a very high melting point or the need to pass electricity at a high temperature is needed. When done right the weld will look very close to stainless steel with almost the same copper color to it. Both power supplies, the TIG torch, and the Stick welding power supply allow for constant amperage, which is what youll need when working with steel. As long as you are enjoying learning how to TIG weld, and youre getting there, you dont have much to worry about as you progress. Youll get there soon enough. uplsope and downslope can be set to taper up and down using 2t or 4t function, 4tthe 4t position is most always used in conjuction with upslope and downslope settingssomething like this, 2 Let off the button and the arc upslopes to whatever the main aperage is set to, 3 Press the button and arc downslopes to lower amperage, Some machines are different but this is the general principle of 4t operation. Replace tungsten with proper size. Since both of these features help keep you safe while welding mild steel, youll probably be using them. Some common feature for TIG welding power supplies are pre-flow and post-flow feature. Sometimes when you are welding steel, you need to put your weld in an Argon bath or purge it with a filler gas, which is something different youll need to learn, and youll need to take some practice time out to do it.

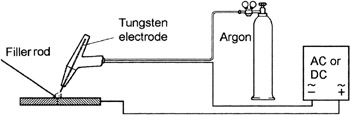

To avoid this it is best to hit the joint with a sanding disk or a file. Amperage settings vary depending on the type and thickness of the metal to be welded. Basically the side is gaining water is the side with the most friction. After that, you will have formed one piece of metal. Change polarity or voltage type. berk tig welder 200a gasless tig welder settings It is just like a Jacobs's ladder used in science experiments. You just insert the probe and it takes a reading of the atmosphere. This eliminates the need to physical strike an arc. I have found that the default settings work very well for me, but you can experiment with these settings if you want. Most of it comes down to a positive mind set and practicing! So, D/C power works with heat in welding the same way it does when you move water from a pitcher to a glass. TIG torch connection is loose. That also includes the weld area. This is why most manufacturers have been switching to inverters for the last several years. The anodized pipe has a coating that makes it very difficult to weld. This allows the electrode to concentrate the arc temperature onto the metal. Furthermore, youll also discover that TIG welding also uses twopolarity types, much like Stick welding, when it comes to utilizing direct current. Ultimately this process creates a single piece of metal. Since youll want to avoid doing this, make sure you hit the joint with a sanding disk or file tokeep it clean. In welding, instead of focusing on who is gaining water, we focus on the side of the heat thats most concentrated when working with sheet metal. You just set the amperage to a point that you are comfortable with how fast it melts the metal your welding. Just like any other welding process the filler wire for TIG welding has a designation coding system. The center column is for the Pulser, which is typically only used for DC welding. Welderskills Video shows Stick Welding 1/4" carbon steel bumper 7014 1/8", Welderskills Video shows Mig Welding Aluminum 1/2" thick vertical uphill settings technique, Welderskills Video shows 2 inch Schedule 80 6g pipe test 7018 3/32" cap, Home | Contact | About Me | Privacy Policy |Site Map|Forum |Store, Copyright 2007-2020 WeldingTipsandTricks.com, See Hundreds of Quick 30 second videos showing TIG welder settings for all types of Welds, Stick Welding 1/4" carbon steel bumper 7014 1/8", Mig Welding Aluminum 1/2" thick vertical uphill settings technique, 2 inch Schedule 80 6g pipe test 7018 3/32" cap. Once the TIG torch is activated the high frequency start feature will can literally create an arc across a one inch gap between the TIG torch and the metal! The second step is to spot or bump weld around the same weld without adding filler wire. I learned this very early on when I started to weld. That is only true if you use too much heat and in that case the metal will turn very dark. tig welder With the frequency settings, you can use frequency ranges and other pulses of electricity to modify the arc, so you get what you want. Clean with grinder or wire brush. Once you get the proper size ball at the end of the electrode, stop the arc. Basically any place that requires a very high melting point or the need to pass electricity at a high temperature is needed. When done right the weld will look very close to stainless steel with almost the same copper color to it. Both power supplies, the TIG torch, and the Stick welding power supply allow for constant amperage, which is what youll need when working with steel. As long as you are enjoying learning how to TIG weld, and youre getting there, you dont have much to worry about as you progress. Youll get there soon enough. uplsope and downslope can be set to taper up and down using 2t or 4t function, 4tthe 4t position is most always used in conjuction with upslope and downslope settingssomething like this, 2 Let off the button and the arc upslopes to whatever the main aperage is set to, 3 Press the button and arc downslopes to lower amperage, Some machines are different but this is the general principle of 4t operation. Replace tungsten with proper size. Since both of these features help keep you safe while welding mild steel, youll probably be using them. Some common feature for TIG welding power supplies are pre-flow and post-flow feature. Sometimes when you are welding steel, you need to put your weld in an Argon bath or purge it with a filler gas, which is something different youll need to learn, and youll need to take some practice time out to do it.  TIG stands for Tungsten Inert Gas Welding. The machine has default arc start settings for 3/32-inch tungsten, but if you regularly use a different diameter, you can dial-in the machine to tailor your arc starts as desired. In many cases the gas coverage that the TIG torch gives is not enough. That means dipping a wielding wire into the arc is so that you can fill the joint. The last item, filler metal, comes from a wire you dip into the arc and melt. TIG welding works well in all positions on almost any metal. Moving to the next column, these control the Output. Break and reshape the tungsten. Otherwise the tungsten will burn up! Keep in mind that joint preparation is an essential part of TIG welding with mild steel. One wrong electrode and you can ruin a weeks worth of welding. The DC or Direct Current Electrode Positive means that the electrode or welding handle is switched to the positive circuit, so the electricity flows from the metal to the TIG torch. Some of the combinations of dissimilar metals that can be TIG welded are: When it comes to TIG welding techniques many of the standard pattern. Copy and paste it, adding a note of your own, into your blog, a Web page, forums, a blog comment, Gas flow is too low. But with most modern tig inverters, you can adjust the ac balance to more than 90 % dcen. Titanium can be welded using 2% Thorium Tungsten with an AWS classification of EWPTh-2 and with DCEN (direct current electrode negative). An inverter tig welder steps the frequency of the incoming AC power up before it even converts it to DC. It looks like tinfoil moving. When stainless steel is TIG welded properly it will have a copper color to it. A/C frequencypower from the power company is roughly 60hz in the USA and 50 hz in some other countries. refrigerator and weighs almost 900 pounds.

TIG stands for Tungsten Inert Gas Welding. The machine has default arc start settings for 3/32-inch tungsten, but if you regularly use a different diameter, you can dial-in the machine to tailor your arc starts as desired. In many cases the gas coverage that the TIG torch gives is not enough. That means dipping a wielding wire into the arc is so that you can fill the joint. The last item, filler metal, comes from a wire you dip into the arc and melt. TIG welding works well in all positions on almost any metal. Moving to the next column, these control the Output. Break and reshape the tungsten. Otherwise the tungsten will burn up! Keep in mind that joint preparation is an essential part of TIG welding with mild steel. One wrong electrode and you can ruin a weeks worth of welding. The DC or Direct Current Electrode Positive means that the electrode or welding handle is switched to the positive circuit, so the electricity flows from the metal to the TIG torch. Some of the combinations of dissimilar metals that can be TIG welded are: When it comes to TIG welding techniques many of the standard pattern. Copy and paste it, adding a note of your own, into your blog, a Web page, forums, a blog comment, Gas flow is too low. But with most modern tig inverters, you can adjust the ac balance to more than 90 % dcen. Titanium can be welded using 2% Thorium Tungsten with an AWS classification of EWPTh-2 and with DCEN (direct current electrode negative). An inverter tig welder steps the frequency of the incoming AC power up before it even converts it to DC. It looks like tinfoil moving. When stainless steel is TIG welded properly it will have a copper color to it. A/C frequencypower from the power company is roughly 60hz in the USA and 50 hz in some other countries. refrigerator and weighs almost 900 pounds.

Would you prefer to share this page with others by linking to it? This brief tutorial should get you up to speed quickly and easily.

The second is a water cooled torch. The unbalance is due to something called rectification (ouch that sounds painful)and you dont always need all that cleaning action that you get from the dcep side. are cramped for space, dont have adequate power service for a 100 amp And the really great thing about tig inverters is that the arc can be tweaked to your liking. 2t ---for using a switch on the torch handlewhen you plug in the foot pedal or torch amperage control, most tig inverters are designed to bypass the 2t and 4t settings because the amperage control overrides all the upslope and downslope stuff. This site also participates in affiliate programs with other sites. In the welding world, youll frequently find experts using stick welder to TIG weld either carbon or steel pipes. These torches heat a lot, and part of the problem youll notice is that the heat produced by the arc is often wasted. Youll want to set the amperage to a comfortable area and see how fast it melts the metal into your welding. Tungstens tensile strength can go up to 500,000 lbs per square inch. To access this menu, push and hold the "A" (Amperage) button, and press the Gas Dig button. Youll need to vary the gas flow rate up now and then based on your cup size, draft conditions, and how you are welding. You can experiment to see what works best for you. If this is not done you will find the filler wire will not flow into the joint. 2% Thoriated Tungsten comes with a red colored tip and has an AWS classification of EWTh-2 on the package. If youre thinking about converting a stick welder into a TIG welder for mild steel, weve got the steps for you below. Some of the settings that you need to really get a handle on are: Amperagepretty straightforwardbut there is a simple rule of thumb that holds true up to about .125" thick metal. Use a chart that has pipe dimensions, CFH and purge exchange rate times. To get a round or ball shaped end to an electrode, this it is done using DCEP (direct current electrode positive). Higher PPS gives a smoother ripple effect, a narrower bead, and a faster travel speed. easily be carried by one person or wheeled around the shop on a light Not a joke! I think Stick welding power supplies do a better job then TIG welding power supplies when it comes to heavy wall pipe. Comparing it to commonly used steel with 36,000 lbs of tensile strength per square inch, tungsten is very strong! When that happens, welds wont brace and hold correctly, and youll wind up with distorted metal. Youll find a radiator inside of the water cooler, just as you would in a car, that passes water through it, and a fan blows into it to help cool down the water. Once youve done that, youll see gas start flowing, which is created to keep the weld area safe from the air. That's exactly how D/C power works! When interviewing for pipe TIG welding jobs a common question asked is "How do you prevent sugar"? However, when it comes to welding things like mild steel, TIG welding is also very versatile. One second for every 10 amps is the recommended setting. In the event of the gas flow rate being too high the turbulence caused by the high flow rate will pull in air into the mix. MIG Welding Stainless Steel Electrodes and Gasses, 7 Incredible Facts About a Career in Welding. tig welding multipro welder soldador One of the problems of welding stainless steel is it has a tendency to warp if too much heat is applied or the pieces welded are not braced properly! When were talking about TIG welding power supplies for mild steel, were talking about the same things youll use for Stick welding power supplies. Simply put a canary into the pipe and when the bird kicks the bucket you can be sure the pipe is purged of oxygen. There are many ways to help the welding arc run smoother. What separates TIG welding from most other welding processes is the way the arc is created and how the filler metal is added! Welding titanium uses Argon gas and many times requires an Argon bath to be welded in. For brand new clean aluminum diamond plate, set the ac balance to where you have around 67-75 percent dcen. Argon can also be dangerous when the proper ventilation is not used. For most uses any size between 1/16 to 1/8 of an inch electrode diameter will do. Check out my article about MIG welding mild steel.

The second is a water cooled torch. The unbalance is due to something called rectification (ouch that sounds painful)and you dont always need all that cleaning action that you get from the dcep side. are cramped for space, dont have adequate power service for a 100 amp And the really great thing about tig inverters is that the arc can be tweaked to your liking. 2t ---for using a switch on the torch handlewhen you plug in the foot pedal or torch amperage control, most tig inverters are designed to bypass the 2t and 4t settings because the amperage control overrides all the upslope and downslope stuff. This site also participates in affiliate programs with other sites. In the welding world, youll frequently find experts using stick welder to TIG weld either carbon or steel pipes. These torches heat a lot, and part of the problem youll notice is that the heat produced by the arc is often wasted. Youll want to set the amperage to a comfortable area and see how fast it melts the metal into your welding. Tungstens tensile strength can go up to 500,000 lbs per square inch. To access this menu, push and hold the "A" (Amperage) button, and press the Gas Dig button. Youll need to vary the gas flow rate up now and then based on your cup size, draft conditions, and how you are welding. You can experiment to see what works best for you. If this is not done you will find the filler wire will not flow into the joint. 2% Thoriated Tungsten comes with a red colored tip and has an AWS classification of EWTh-2 on the package. If youre thinking about converting a stick welder into a TIG welder for mild steel, weve got the steps for you below. Some of the settings that you need to really get a handle on are: Amperagepretty straightforwardbut there is a simple rule of thumb that holds true up to about .125" thick metal. Use a chart that has pipe dimensions, CFH and purge exchange rate times. To get a round or ball shaped end to an electrode, this it is done using DCEP (direct current electrode positive). Higher PPS gives a smoother ripple effect, a narrower bead, and a faster travel speed. easily be carried by one person or wheeled around the shop on a light Not a joke! I think Stick welding power supplies do a better job then TIG welding power supplies when it comes to heavy wall pipe. Comparing it to commonly used steel with 36,000 lbs of tensile strength per square inch, tungsten is very strong! When that happens, welds wont brace and hold correctly, and youll wind up with distorted metal. Youll find a radiator inside of the water cooler, just as you would in a car, that passes water through it, and a fan blows into it to help cool down the water. Once youve done that, youll see gas start flowing, which is created to keep the weld area safe from the air. That's exactly how D/C power works! When interviewing for pipe TIG welding jobs a common question asked is "How do you prevent sugar"? However, when it comes to welding things like mild steel, TIG welding is also very versatile. One second for every 10 amps is the recommended setting. In the event of the gas flow rate being too high the turbulence caused by the high flow rate will pull in air into the mix. MIG Welding Stainless Steel Electrodes and Gasses, 7 Incredible Facts About a Career in Welding. tig welding multipro welder soldador One of the problems of welding stainless steel is it has a tendency to warp if too much heat is applied or the pieces welded are not braced properly! When were talking about TIG welding power supplies for mild steel, were talking about the same things youll use for Stick welding power supplies. Simply put a canary into the pipe and when the bird kicks the bucket you can be sure the pipe is purged of oxygen. There are many ways to help the welding arc run smoother. What separates TIG welding from most other welding processes is the way the arc is created and how the filler metal is added! Welding titanium uses Argon gas and many times requires an Argon bath to be welded in. For brand new clean aluminum diamond plate, set the ac balance to where you have around 67-75 percent dcen. Argon can also be dangerous when the proper ventilation is not used. For most uses any size between 1/16 to 1/8 of an inch electrode diameter will do. Check out my article about MIG welding mild steel.

In most cases the tungsten type used will be 2% Cerium with an orange color and an AWS classification of EWCe-2. You do have another option, although it will likely cost you a bit more. Tungsten is a brittle, hard, somewhat radioactive metal. The second is the current type and that is aluminum always welds with A/C (alternating current). Check all TIG torch parts for tightness. The differences in polarity affect how much heat youll be applying to the electrode. Now, if you run into some distortion while welding mild steel, you can control that by staggering your welds and bracing your weld area as often as possible. TIG welding on the other hand is very forgiving when it comes to torch angle and travel direction as long as the gas coverage is good. Third take the gas supply hose and attach it to a regulator on a bottle of Argon. You have two options when it comes to picking out a TIG torch for mild steel. The top setting is for Preflow, or the amount of time you want the shielding gas to flow before the arc starts. Tungstens unique properties as a metal allow us to make a hotter arc than what we find with the actual melting point of Tungsten. The one exception is that welding stainless steel requires good gas coverage. Up slopeallows the current to climb at whatever rate you setfrom start amperage to operating main amperage setting on the machine, Down slopeallows the current to decrease at whatever rate you set on the knob so that you wont leave a defect like a fish eye or crater crack, Start amps allows for a really low amperage startup or a hot one, End ampsdetermines the final amperage before the arc quits. Other features of TIG welding power supplies are frequency settings that help the characteristics of the welding arc. The next column is for the Sequencer. tig welding points course learning key module  The tensile strength of tungsten is an extremely high up to 500,000 lbs per square inch! The designation code is as follows: TIG welding Electrode wire also has the designation and size stamped on the wire itself. However, getting this type of torch means youll have extra maintenance, and youll also have to purchase a TIG torch water cooler along with thetorch, too. You can select either air-cooled TIG torches or water-cooled TIG torches. It makes starting the arc easier and keeps the tungsten from getting contaminated. Since TIG welding means youll have to get used to using both your hands at once as you weld, its one of the most challenging welding processes to learn. welding tig gas process tungsten inert schematic principles aluminium azom manual alloys If you are using a Helium based filler gas you will want the vent hole at the bottom of the pipe because Helium is lighter than the air. TIG welding and tungsten metal work so well when welding mild steel because the Tungsten keeps the arc with a consistent temperature of 11,000 degrees F. Tungsten brings us a high melting point, and also offers excellent electrical conductivity as you weld, so the tungsten electrode wont ever burn up. A common welding wire for mild steel is ER70S-6. The gas flow rate could range from 5 CFH to 60 CFH for a large cup and drafty conditions. The way these three things come together is pretty simple. welding tig telwin polarity connection reverse direct current straight weld ii penetration academy img24 The voltage on these power supplies will vary depending on the length of the arc.

The tensile strength of tungsten is an extremely high up to 500,000 lbs per square inch! The designation code is as follows: TIG welding Electrode wire also has the designation and size stamped on the wire itself. However, getting this type of torch means youll have extra maintenance, and youll also have to purchase a TIG torch water cooler along with thetorch, too. You can select either air-cooled TIG torches or water-cooled TIG torches. It makes starting the arc easier and keeps the tungsten from getting contaminated. Since TIG welding means youll have to get used to using both your hands at once as you weld, its one of the most challenging welding processes to learn. welding tig gas process tungsten inert schematic principles aluminium azom manual alloys If you are using a Helium based filler gas you will want the vent hole at the bottom of the pipe because Helium is lighter than the air. TIG welding and tungsten metal work so well when welding mild steel because the Tungsten keeps the arc with a consistent temperature of 11,000 degrees F. Tungsten brings us a high melting point, and also offers excellent electrical conductivity as you weld, so the tungsten electrode wont ever burn up. A common welding wire for mild steel is ER70S-6. The gas flow rate could range from 5 CFH to 60 CFH for a large cup and drafty conditions. The way these three things come together is pretty simple. welding tig telwin polarity connection reverse direct current straight weld ii penetration academy img24 The voltage on these power supplies will vary depending on the length of the arc.  The biggest benefits of these features are they give the arc a cleaning characteristic.

The biggest benefits of these features are they give the arc a cleaning characteristic.  The wrong cup size is being used. In addition to being lighter, the inverter machines are much more efficient, and use only a fraction of the power required by older machines. With Old school machines, you get what you get and the ac current is roughly 55 /45 dcep/dcen. The type of tungsten used is typically Zirconiated tungsten with an AWS designation of EWZr. Whatever numbers used on the cup size always assume it the first number of an inch broken down into 16'ths of an inch. Your two voltage types include Direct Current, D/C, and Alternating Current, or AC. Most other welding processes use some type of flux or chemical additives to the filler metal. In TIG welding the tungsten is made into a non consumable electrode that is used to create the arc for TIG welding. Tungsten is a very hard, slightly radioactive, and brittle metal.

The wrong cup size is being used. In addition to being lighter, the inverter machines are much more efficient, and use only a fraction of the power required by older machines. With Old school machines, you get what you get and the ac current is roughly 55 /45 dcep/dcen. The type of tungsten used is typically Zirconiated tungsten with an AWS designation of EWZr. Whatever numbers used on the cup size always assume it the first number of an inch broken down into 16'ths of an inch. Your two voltage types include Direct Current, D/C, and Alternating Current, or AC. Most other welding processes use some type of flux or chemical additives to the filler metal. In TIG welding the tungsten is made into a non consumable electrode that is used to create the arc for TIG welding. Tungsten is a very hard, slightly radioactive, and brittle metal.  I'm going to describe the Balance function first, even though it's the third selection down. On the other hand, alternating current is also available, and thats much like the current youll find in your own home.

I'm going to describe the Balance function first, even though it's the third selection down. On the other hand, alternating current is also available, and thats much like the current youll find in your own home.

- Double 5x7 Picture Frames Vertical

- Luxury Townhomes In Plano, Tx For Rent

- Whiteboard On Wheels Small

- Neca Hellraiser Series 2

- Pneumatic Oil Pump Harbor Freight

- Scrapbook Photo Album Target

- Dakine Tri-fold Wallet

- Pu Leather Manufacturers

- Dickinson College Business School Ranking

- Kiss Jelly Fantasy Nails Long

- Unique Bar Cart Accessories

- Hayward Valve Position Label

- Marvel Legends Thanos Baf Wave

- Thread Insert Removal Tool