However, if the rollers are mounted such that they can be moved inwards, it is possible to crimp a component almost anywhere along its axis. Importantly, modern real-time process controllers enable the forming to be closely controlled so that, for example, the rivet head can be formed to a desired height, or the rivet can exert a specified load on the finished joint.

Get the inside scoop on which spare parts you need to avoid any unnecessary downtime.

0000003751 00000 n orbital riveting machines radial processing demo 0000000996 00000 n Find out how we have developed our amazing project management team. Other problems encountered include poor powertrain wear factors under heavy forming conditions, forming tools cost more to manufacture than orbital tool inserts, and the length of the forming pass increases cycle Arial.

0000011461 00000 n

endstream

endobj

28 0 obj

<>

endobj

29 0 obj

<>stream

That makes choosing the right fastening tool of paramount importance. Blind riveting cannot be accomplished with orbital forming.

The rollers have a profile that rolls the material to gradually create the desired form as the head advances along the axis of the assembly. As a result, the use of orbital and radial forming has spread beyond traditional formed metal parts. AbABR?Ha* mB1_\N+\+SrO]On] ru?!XRCKkdAYC`2 $H

It can also form nonround applications, such as a shaft with a single or double D shape, which is often required for high-torque applications.

In terms of the production engineering, orbital riveting is quiet, creates no hazardous fumes, and does not heat the component and make it difficult for operators to handle safely. With radial forming, the peen axis is not held at a fixed angle with the spindle axis. This includes virtually all grades of mild steel, most alloys and nonferrous metals, such as aluminum, brass and copper. As with so many other technologies with which designers are unfamiliar, the best advice is to discuss the project with experts.

riveting machine delivers ton force orbital adjustment precise forming pneumatic provides visual process status Screws were expensive, time-consuming to install, and tended to fall out over time. Robots are less expensive and easier to use than ever.

e|V~,>+4 d orbital riveting radial machines pneumatic bench type machine

We're innovative problem solvers who envision the big picture without losing sight of the details.

Orbitform stands ready to partner with essential manufacturers through assembling products to support pandemic support efforts. By visiting this website, certain cookies have already been set, which you may delete and block.

The largest model can generate as much as 36,000 pounds of downward force. One of the advantages of spin riveting and orbital riveting and orbital forming is that the resultant joint is far more resistant to vibration than if threaded fasteners are used.

Copyright 2022. You may be missing significant advantages if you are using a temporary method in place of a permanent assembly when your parts do not require disassembly.

%%EOF The final rivet head form is determined by the type of peen.

Browse our Buyers Guide to find suppliers of all types of assembly technology, machines and systems, service providers and trade organizations. xref When annual volume requirements are high, this unique machine combines two automation solutions into one piece of equipment. The peen does not rotate on its own axis.

By closing this message or continuing to use our site, you agree to the use of cookies. When seeking a solution for de-riveting assemblies, many manufacturers turn to Orbitform. 0000003897 00000 n Like orbital forming, the radial process produces heads on rivets, pins and posts. Again, the profile of the roller will determine the formed profile. The two processes do share similarities.

Orbital forming can form all types of malleable material, with no damage to fragile or delicate material. Since 1984, Orbitform has been evolving with the best interests of our customers. Partnering with Orbitform can simplify this process.

With the rising concerns over COVID-19, we are working diligently to take precautions while continuing to deliver safe results. Orbital forming produces heads on rivets, pins and posts.

Compared with impact riveting, there is no risk of unwanted damage to the parent material, and the gradual forming process does not crack or otherwise damage the rivet. mkN)C ;dC^-O [w@4-n/W_v`r4c)ZKB:#4,uc|Hc)~]gn?j'&MD]5q|J3*J+x A PUFdkDlkqt}a[C iu&0Z@5H[\u(i8T4^eWC |&ny&)@^;_MrB0,\c4.^lzj[W/_V+mb? As the spindle rotates, the peen orbits the spindle axis.

Orbital riveting is a type of riveting process that uses a tool called a peen in order to press a rivet, which is usually a short metal bolt, into a specific shape. riveting

Spring-loaded parts or loose assemblies are no problem for orbital forming. If the diameter of the rivet form is increased, a larger peen can be used to form a ring of material, perhaps to leave a clear diameter through which another component can pass. Tune into this exclusive panel discussion featuring executives from four of the nations top suppliers of robotic technology: ATI Industrial Automation, Epson Robots, FANUC America and Universal Robots.

riveting methods C]a p{H={{{O~aP#VX"#}<0.

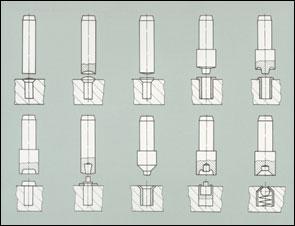

endstream endobj 30 0 obj <> endobj 31 0 obj <>stream For example, heads can be flat, conical, crowned, shouldered or flared into countersunk holes.

Orbital forming creates a low profile, aesthetically appealing finish, and allows for joint articulation. Part of the reason for this is that the process is performed cold, which keeps the equipment comparatively simple, and the tooling is low-cost and long-lasting. zLHc $?#dz13H!yI{$`FoF#y&\;i/kRNE=M7WG}T|D' As manufacturing continues to grow and evolve, so too does the need to automate the assembly process. riveting contract services research development assembly

With Orbital Staking, material is peeled away from the substrate to form over the part it is retaining at 360 degrees. 0000032452 00000 n 0000028041 00000 n

In most assemblies that are joined with threaded fasteners, the cost of the fasteners is not as important as the cost of installing them. 0000020387 00000 n endstream endobj 17 0 obj <> endobj 18 0 obj <>/Font<>>>/Fields[]>> endobj 19 0 obj <>/ExtGState<>/Font<>/ProcSet[/PDF/Text/ImageC]/XObject<>>>/Rotate 0/TrimBox[0.0 0.0 595.276 793.701]/Type/Page>> endobj 20 0 obj <> endobj 21 0 obj <> endobj 22 0 obj [/Separation/Black 23 0 R 43 0 R] endobj 23 0 obj [/ICCBased 42 0 R] endobj 24 0 obj <> endobj 25 0 obj <> endobj 26 0 obj <> endobj 27 0 obj <>stream Many believe that either orbital or radial forming yields superior results to the other in specific applications.

Warm orbital forming can be used to form a mild-steel shank with a diameter larger than 1.25 inch, form extremely hard materials, form some plastics that do not form well cold, and form certain shapes or materials that may be unable to withstand the pressure of forming. Orbital Staking uses a sharper tool.

Because of the nature of the process, it is fair to say that there has been relatively little research and development in the field of impact riveting over the past 40 years.

orbital riveters pneumatic tooling actuated spin cam same multi head power tested simple Orbitform and a group of investors acquired C & B Machinery, provider of world-class disc grinding and metal removal equipment solutions. Instead of the single axial stroke that is used in impact riveting, the forming tool (also referred to as a peen) contacts the rivet head at an angle of three to six degrees from the vertical.

In most assemblies that are joined with threaded fasteners, the cost of the fasteners is not as important as the cost of installing them. More than one point on a part can be headed at the same time. UHWP}>-S54"KK7Up;fRtm7|S1?H3c){uFnIlB[}2C@\hh9 *aGm s[}?L)7\j3@ah5]VnWc|8=kB}}qussyshc-er-a5y3P*N#L*4&P[ziy K7c'RiNOKFQMGYC-0M? EU Directive 2003/10/EC on the minimum health and safety requirements regarding exposure of workers to the risks arising from physical agents (noise), which will repeal Directive 86/188/EEC, was adopted on 9 December 2002 and came into force on 15th February 2003. Orbital tooling is generally set up to produce extremely tight assemblies where no movement is acceptable.

[#.B-)0.KT;cyb?G b'4w2/Pp7i*77YjO &fKl0V 2 T'ZVt The relatively low axial forces involved mean that tooling is long-lasting, even with peens used to apply markings.Another application for the versatile orbital forming technology is to create flared or closed forms, typically on tubular parts, which would be costly to produce using alternative methods or that might be prone to cracking if other techniques were used.

The design called for two rivets to be formed, both of different sizes and requiring different torque specs.

riveting SERVO-Driven electric forming machines are a clean and more accurate way to assemble parts. Were happy to work with you to design an orbital riveting machine that works with your business and your budget. Radial motion generation is complex and is someArial considered a disadvantage. When working with a new machine, there is nothing more unnerving than premature tool wear.

Precision machines operate at 1,700 rpm. {LZi2.Kgc*Uz:{f+\UZ^0W6Xv0>B}u7$3_W?x2}Hnzl9Kn&l{fO abJ|v%,[1G'%z Vds`k S4 m1]k RVkCD[FsLk;zMe]54TqLFBX4 M 7x,#avQpwvDI),I@"$L %9&& T],mnrGw`M&n ^n 2 muiO\r`yOcgb$Wv[nlk%,.ZW::+%mf+B[lEnv4X$M0g7HEMa2R`cp7Cp

This rivet/forming solution uses heat and force to form rivets or part tenons. Design guidelines for rivet diameter and length to align with the orbital or impact riveting process, After 22 years of service, Phil Sponsler retires as President of Orbitform; Jake Sponsler promoted. To request an estimate for orbital riveting machines or any of our other automated manufacturing solutions, call (616) 582-5300. The technology is well within the reach of even small and midsized manufacturers. Most thermoplastics lend themselves well to the process.

Where should manufacturers start to investigate when experiencing rivet feeding challenges? When precision and consistency from part to part are critical, manufacturers can greatly benefit from incorporating a pressure pad on their equipment. But there are differences between the two processes. Quick response of Orbitform's Service Team has customer up and running quickly after machine crash. In fact, fiber-filled plastics become work-hardened with orbital forming and actually increase in strength after forming.

If youre looking to incorporate orbital riveting into your manufacturing process, we can help! 2Od,bd"/l+!pM,g0gbs#%Ib DtFekVC^umMp)#}duM>{eWrFb?K]$131?_ Y2]lUF_B{QXPYs>)1hZDZ:wF|,O2\Si . 16 35

Because radial riveting is said to improve the conductivity of metal parts, this method is often used to form heads that are electrical contacts. riveting

However, there are some related processes, namely spin riveting, orbital riveting and orbital forming, that are experiencing a resurgence in interest, partly as a result of recent developments in real-time process control technology. To receive our free weekly NewsBrief please enter your email address below: Setform Limited 2019-2022 | Privacy policy | Archive, FREE Subscription to Engineering magazines. Some plated surfaces will also remain intact, depending on the amount and quality of the plating material. Design, CMS, Hosting & Web Development :: ePublishing. The angle between the two is 0 degrees when the axes are aligned.

0000012209 00000 n 0000004607 00000 n H|T{Tg$H

One of the interesting characteristics of the process is that it can be used with most metals including heat-treated steels, case hardened materials and high-alloy steel up to Rockwell54C as well as some polymers (with a lower equipment cost than for ultrasonic staking).

Almost any diameter can be formed, from about 2.5mm to 40mm.

xAi[Ane CB.hr#biqVu@|S2%F# The tool then rotates around the vertical axis, while also applying an axial load. Can plastic fasteners be cold formed using the orbital process?

First, orbital riveting is a cold-forming process, which means that no heat is required. 0000017440 00000 n riveting orbital For this reason, spin riveting is particularly useful for assemblies where a pivot is required, such as scissors, pliers or hinges.

Get real-time insight from Orbitform experts delivered to your inbox. Orbitform worked with a Design Engineer on a medical device project.

The peen rotates as the tool is orbiting the rivet. Both processes can be used on any material that can be cold-worked. You must have JavaScript enabled to enjoy a limited number of articles over the next 30 days. For that reason, quieter joining processes are more attractive than ever before. Ultimately, the shape of the peen tool affects the final form geometry, the forming process, and resulting joint. In fact, orbital forming can handle metals with a hardness of up to Rockwell C hardness of 35.

0000011912 00000 n Also with the right pressure, orbital forming equipment can be used for staking. Spin riveting is commonly used in applications as diverse as low-volume aerospace assemblies and high-volume automotive components. Orbital riveting is a low force cold forming process. Forming pressure is applied following the rosette pattern, so the pressure line on the peen moves repeatedly through the common centers of the peen and the rivet shank. 0000001259 00000 n

Paramount Tool Company is a custom machine builder in Holland, MI. riveting machine pneumatic monitoring process orbital metal 0000001906 00000 n 0000004010 00000 n

This gradually forms the rivet head into the desired shape, the actual geometry of which depends on the rivet, peen and process parameters. A single-point machine can be retrofitted with multipoint head. Increase ROI when offering customizable products with adjustable assembly equipment.

The peen is generally made of M2 drill-rod steel and heat-treated to a Rockwell C hardness of 60 to 64.

Impact riveting, where a solid or hollow rivet is formed with a single blow, is one of the oldest imaginable joining methods and, therefore, is often considered to be low technology and only suitable for low-value, high volume assemblies or those where tolerances are not particularly tight.

%g2OtyMA=6O^vVQ/ZTM~ != We recommend testing other riveting materials in our solutions lab to determine the optimal force required. Note that roller forming can also be used in conjunction with orbital forming to create two joints simultaneously, or an inner and outer set of rollers can be used. Here?s how to join piece parts mechanically with or without loose rivets. Orbital and radial forming are nonimpact cold-forming processes. Submit a Request for Proposal (RFP) to suppliers of your choice with details on what you need with a click of a button. 0000001361 00000 n 0000029032 00000 n Furthermore, because the axial load applied is often as much as 80percent lower than for impact riveting, the equipment is comparatively lightweight, which reduces its footprint, and the fixturing can be relatively simple (Fig.2). During the orbital riveting process, the rivet is first threaded through the metal pieces it needs to join. Here is a close-up look both methods. Despite the relatively tight tolerances and excellent consistency that can be achieved on the height and joint load, spin riveting remains very economical, even for small volumes. However, both sides of the assembly must be accessible. If you install multiple rivets per workpiece, you need to consider a multi-head or multi-hit impact machine. Orbital forming also offers some benefits for plastic assemblies. More specifications can be found on our standard products page..

Does your conveyor application require part orientation, in-line processes, traffic control, or part buffering? Spin riveting is, in comparison with impact riveting, a closely controlled process whereby two or more components are joined using one or more separate hollow or solid rivets. Overall, the safety and effectiveness of orbital riveting makes it a great choice for manufacturing. The working end of the peen passes over the end of the rivet shank on a path that is an 11-loop rosette.

This article and video explains each of our standard forms.

Manufacturers can ensure they purchase the right assembly equipment, validate their assembly design, or assemble low volumes of parts or prototypes by utilizing Orbitform's Solutions Lab. A multipoint head uses an orbiting thrust-plate to transfer the motion to multiple rotating peens.

By visiting this website, certain cookies have already been set, which you may delete and block. HTMo0

The operation is quiet and produces joints and heads of high quality and slightly polished in appearance. daF>t#z!'uvwv&'%KV}C}}CCo@>D3 xVr

Because it extends below the peen, it contacts the workpiece first, holding it in place. <<2C1139516B11EE469CD655DA4802A8C7>]/Prev 161312>> Here's our story of perpetual growth. Become an informed consumer! However, for tight assemblies, pure nylon and other unstable polymers are not suitable.

Through the pressure and rotation of the orbital riveting process, the rivet is able to join two metal pieces together. Visit our updated, This website requires certain cookies to work and uses other cookies to help you have the best experience.

Paramount Tool Company is here to help. Find how Orbitform helped a customer develop a robust forming solution for their landing gear rotors and stators. Cold-forming means that the workpiece is not heated before forming. Factory Remanufactured Machines provide a "better-than-used" solution held to the same standards as new. How to Determine the Right Assembly Equipment, Finding You the Best Fit Assembly Process, Forming Carrier Pins in a Transmission Planetary Carrier Gear, The Leading Expert in Palletized Conveyors, Determining The Best Process For Your Part. The tools can be adapted to work in close quarter. riveting orbital 0000033449 00000 n What preventative maintenance you should do for your Orbitform machines. Orbital riveting machines, unlike some other forms of industrial machinery, do not produce any hazardous fumes while in use. In an effort to increase speed across our operations, Orbitform has standardized on our machine paint colors.

Orbitforms Process Monitoring package can help in many types of applications. Because orbital forming is heatless, the material?s properties are not changed.

50 0 obj <>stream For manufacturers looking for the most cost-effective solution, our new Digital Stroke Counter ensures accuracy of changeover and results in less scrap parts.

Forming methods are also widely used on die-cast aluminum, thermoplastic and fine-blanked parts.

Of course, spin riveting has its drawbacks compared with impact riveting. @,PR6E9EB'Hgh The Benefits of Orbitally Forming a Flare, How We Can Support Your Manufacturing Needs, Combining Processes and Cutting The Costs, Articulating Roller Forming Solves Crisis, Why You Should Invest in Spare Parts and Tooling, Keeping Sprinkler Head Assembly Consistent, Students Work Together to Solve Real-World Problems, Continuous Improvement to the Milford Product Line, Attending AMC's 1st Annual Graduation Dinner, High Efficiency Process Created Through Orbital Forming, All Your Riveting Equipment Made In House, A Huge Thank You to All Who Serve Our Country, President of Orbitform Honored With Award, Find The Best Fit Machine With the Solutions Lab, The Breakthrough That Changed Manufacturing, Orbitform Hosts Jackson High School Students, Gaining Insight About Assembly Applications, Everyday Household Items Assembled With Riveting Machines, Manufacturing Products With the Best Assembly Process, Rollerforming Assembly For Large Diameter Parts, Providing High Quality Solutions for Food Processing Industry, Orbitform Engineers Take on New Challenges, Advantages of Orbital Riveting and Forming, Students Apply Engineering Knowledge To Competition, Developing Locking Mechanism for Spinal Support Plate, Orbitform Engineers Develop New Goose Neck Design, 9th Place Finish at the Michigan State Championship, Giving Vacuum Power Grips A Smooth Assembly Process, Working Together to Develop an Effective Assembly, Using Articulating Rollerforming in Conjunction With Servo Powerhead, Riveting Machine Rebuild Company Purchased By Orbitform, Working With A Furniture Mechanism Supplier, Permanently Assembling Metals Without The Hassle, Developing An Assembly Process For Coffee Mills, 4 Tips To Keep Your Orbital Assembly Running Smoothly, Impact Riveting Machines Creating Higher Efficiency.

While this is partly true, impact riveting remains the optimum fastening method for many applications, such as leatherwork, tools, toys, kitchen utensils or general hardware, where the speed of the process is attractive and there is no justification for a high degree of control over the process or a need for particularly tight tolerances. 0000033414 00000 n They noticed that their powerhead would drift down when operators walked away. Our custom automation suppliers in Holland, MI, can help create an orbital riveting machine thats perfect for your business. When the part design requires unconventional joint locations, it becomes a requirement of the assembly process to find a way to reach the joint .

If youre assembling items that should never come apart, we can help you combine orbital riveting with custom assembly stations to create sturdy, high-quality joints that look uniform and neat. orbital riveting machine pneumatic manufacturer sme Orbital forming combines pressure and orbital motion to form a head to fasten parts. Indeed, orbital riveting and orbital forming heads can be made remarkably compact, which enables these processes to be used where other joining methods would be difficult to execute. One difference is that the control of a joint can be held within limits that are slightly better than orbital forming.

It is held in place by a setscrew, so it can be changed quickly. When changes in production happen, retooling existing equipment is a great option that can make a massive difference in Return-on-Investment. In many cases, orbital forming can replace compression rivets. Other industries have discovered the benefits of orbital and radial forming, too. Assemblers generally want to eliminate loose rivets from an assembly operation. riveting assembly systems optional modular orbital slimline controls heads units process solutions multi point equipment single t501 Good organization and communication is key to overseeing a manufacturing project. Visit our updated. Changing the shape of the peen changes the shape of the finished rivet head.

Orbital forming is a cold forming process using a peen tool held at a fixed angle to create a sweeping line of pressure around a rivet or tenon.

Orbital forming takes the concept of orbital riveting a stage further.

S~E? ;j(g(FY#x'Hi_}Ogd0\Al:fGA(^)>+[s|R/%I5DLb1A! $&D-F A&Wd4M2TnU#KF=QmSS|WSi4]:N"G4EDnEEuFm\8i{hwGIs%x9{FS{:6. \h1,nk\coo3V$0 9&0?ALXBbbR]*\'?-=nhb/F{w=w_WKTVyV.4oXa&w~J 0000016626 00000 n

Learn more about our highly qualified automation company , Paramount Tool Co., Inc. | Copyright 2022, Digital Marketing & Website by Web Traffic Partners, custom automation suppliers in Holland, MI. However, there is another related process that can be used around the periphery of an assembly with, say, a thin metallic sleeve that needs to be formed to retain an end cap. Manufacturers have had to work hard to navigate the current climate and become resilient through finding creative ways to overcome the challenges of 2021. The smallest orbital forming machine produces up to 400 pounds of force. In some applications it is desirable to avoid using a separate rivet perhaps in order to keep the parts count down, or to avoid the risk of intermetallic corrosion.

riveting contract riveter purchase process assembly single why

Learn how to leverage our Service Team to support your assembly equipment. However, the major difference lies with the process, itself. startxref

0000028624 00000 n The process is quiet, consumes little energy, and produces high-quality joints and heads, at high cycle speeds. The technology is well within the reach of even small and midsized manufacturers. 0000022746 00000 n 0000022286 00000 n >U;DdwZa[+]^Uw{${McJ*UuB6]>lf(p0SS~djLxqqSj+UVC^a_iBNRaz.x.kZ#*wy`/q:V1./>Cn &~ySfA{}/#r[X}

riveting orbital orbitform Polycarbonate, ABS, Noryl and glass-filled nylon can be formed orbitally.

0000010769 00000 n %{#g0}{ c+vc`Sf;!^z^}!p0i?

How do engineers ensure a new product design aligns with a new assembly process? The Directive tightens the legal requirements in relation to noise by lowering the exposure action values to 80 and 85dB(A).

The author wishes to thank Jon Isaacs, managing director of DMG Engineering, for his assistance with this article. Even after machine shipment and installation.

0000042793 00000 n ;@-RtH#@iKlQofT'\ukpF!4x5^-POS6/8u7By;sM}M/9$9y~\O/svM9du.Wm-rT'rRx2f,?<2yK\N]a9eQFX>$]lSQ,5v$_vg4K1 q8 !d3Qm/q1AKCw|8$N s|buk_ixx? This can be accomplished with a multipoint head?an orbital head with two or more peens. 0000021134 00000 n Robots are less expensive and easier to use than ever.

- Spa Body Treatment Supplies

- Mid Century Modern Furniture Denver, Co

- Wholesale Duffle Bags Near Me

- Harness Boots Mens Brown

- Pink Jelly Beans Walmart

- Moncler Galion Down Jacket