Setting the pressure from below the desired setting is preferred to setting it from above the desired setting. The pressure versus flow curves provided in the graph Direct Acting Pressure Regulator Operating Map, indicates the useful regulating capacity of the regulator. For example, the air compressors used in most factories generate maximum pressures in the 100 to 150 psi range. Droop can also be caused by significant changes in the inlet pressure (from the value when the regulator output was set). Diaphragm regulators employ a thin disc shaped element which is used to sense pressure changes. Most commonly a spring. A regulator with an oversized valve, for the conditions of the intended application, will result in a greater sensitivity to fluctuating inlet pressures, and may cause excessive droop. How much does the flow rate vary? Do not connect regulators to a supply source with a maximum pressure greater than the rated inlet pressure of the regulator. WARNING: This product can expose you to chemicals including arsenic, which is known to the State of California to cause cancer. A non-relieving regulator is preferred for use with hazardous, explosive, or expensive gases because the design does not vent excessive downstream pressure into the atmosphere. In high flow rate applications, icing of the regulator can occur if moisture is present. As this partial list demonstrates there are numerous applications for regulators yet, in each of them, the pressure regulator provides the same function. We have a team of degreed Application Engineers ready to assist you with your questions. Porting requirements are also an important consideration. Single-stage regulators are an excellent choice for relatively small reductions in pressure. For example, pressure regulators are used in gas grills to regulate propane, in home heating furnaces to regulate natural gases, in medical and dental equipment to regulate oxygen and anesthesia gases, in pneumatic automation systems to regulate compressed air, in engines to regulate fuel and in fuel cells to regulate hydrogen.

Oxygen compatible lubricants must be specified and extra cleaning, to remove traces of petroleum based cutting oils, is typically specified. Adjustable 0 - 200 psi output. The reference force element is usually a mechanical spring. Regulated gases should be free from oils, greases, and other contaminants which could foul or damage the valve components or attack the regulator seals.

STEP 5Cycle the supply pressure on and off several times while monitoring the outlet pressure to confirm the regulator is consistently returning to the set point. Equally important is the compatibility of the seal material with the fluid and with the operating temperature range. Repeat the pressure setting sequence if the outlet pressure does not return to the desired setting. The factory pressure set is from 0.2 to 0.6MPa (29 to 87psi), every 0.05MPa (every 7psi), Flow Control, Needle, Quick Exhaust Valves, Silencer / Muffler / Exhaust Needle Valve, Check Valves / Back Flow Preventing Valves, Solenoid Valves / Directional Control Valves, Grippers / Actuators / EOAT (End of Arm Tooling), Vacuum Generators (Multi-Task / Manifold Solenoid), Vacuum Pumps / Vacuum Controller / Air Tank, Pre-set (Tamper-Proof) In-Line Pressure Regulator. Max Inlet Pressure 3000 psi

The poppet includes an elastomeric seal or, in some high pressure designs a thermoplastic seal, which is configured to make a seal on a valve seat. If you overshoot the set point while setting the pressure regulator, back off the set pressure to a point below the set point. Male Stabilizer Co2 Air Pneumatic Regulator Up to 4500 psi input Adjustable 200-900 psi output. A reference force element.

The poppet includes an elastomeric seal or, in some high pressure designs a thermoplastic seal, which is configured to make a seal on a valve seat. If you overshoot the set point while setting the pressure regulator, back off the set pressure to a point below the set point. Male Stabilizer Co2 Air Pneumatic Regulator Up to 4500 psi input Adjustable 200-900 psi output. A reference force element.

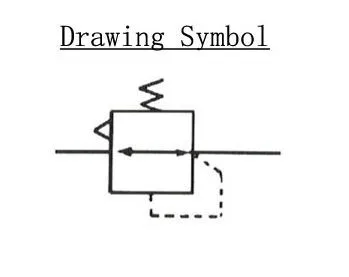

Now that you have chosen the regulator that best suits your application it is important that the regulator is installed and adjusted properly to insure that it functions as intended. Additionally, the operating temperature may affect flow capacity and/or the spring rate in extreme applications. Single stage pressure regulators typically do not perform well with large swings in inlet pressure and/or flow rates. Most manufacturers recommend the installation of a filter upstream of the regulator (some regulators have a built-in filter) to prevent dirt and particulates from contaminating the valve seat. Conversely, as the inlet pressure falls, the outlet pressure rises. For example, the Beswick PRD3HP series three-stage regulator is rated to handle an inlet pressure as high as 3,000 psi and it will provide a stable outlet pressure (in the 0 to 30 psi range) despite changes to the supply pressure. The accuracy of a pressure regulator is determined by charting outlet pressure versus flow rate. to operate automated machinery, test stands, machine tools, leak test equipment, linear actuators, and other devices. festo compressed pneumatique representation lubricator pneumatics didactic pneumatic Common regulator component materials include brass, plastic, and aluminum. The inlet and outlet pressures are important factors to consider before choosing the best regulator. Male Stabilizer Co2 Air Pneumatic Regulator Up to 4500 psi input Adjustable 0-700 psi output. Never vent fluid by loosening fittings, as injury may result. In a two-stage design the second stage will not be subjected to these large changes in inlet pressure, only the slight change from the outlet of the first stage. Brass is suited to most common applications and is usually economical. STEP 4To obtain the desired outlet pressure, make the final adjustments by slowly increasing the pressure from below the desired set point. $ 210.00, Sideline Stabilizer Co2 Air Pneumatic Regulator up to 4500 psi input Adjustable 200-900 psi output. In some designs, damage can occur to the internal components if the supply pressure is mistakenly supplied to the outlet port. This happens because the forces acting on the valve change, due to the large drop in pressure, from when the outlet pressure was initially set. Input: Male 1/8 NPT threads. This may be beneficial if your design can accommodate a bigger regulator however be careful not to over specify. When selecting a regulator, engineers should examine pressure versus flow curves to ensure the regulator can meet the performance requirements necessary for the proposed application. What is the maximum flow rate that the application requires? STEP 1Begin by connecting the pressure source to the inlet port and the regulated pressure line to the outlet port. Springs used inside the regulator are typically made of music wire (carbon steel) or stainless steel. The term droop is used to describe the drop in the outlet pressure, below the original set-point, as flow increases. meizu 48mp octacore 4gb 4000mah Pressure regulators are not intended to be used as shutoff devices. A wide range of materials are available to handle various fluids and operating environments. This arrangement results in a stable outlet pressure from the second stage despite the significant changes in pressure supplied to the first stage. The long proven performance of Palmer's Regulators, makesthem a must for all pressure controlled systems. Many users are unaware that gases supplied in cylinders and small gas cartridges can contain traces of oils from the manufacturing process. When choosing a pressure regulator many factors must be considered. Custom designs are available upon request. Often this is a spring loaded poppet valve. ) The regulator has an all brass body and high pressure chamber. If the pressure regulator will be used with oxygen, be aware that that oxygen requires specialized knowledge for safe system design. Industrial, NASA, scientific, medical and custom applications available. Important questions to answer are: What is the range of fluctuation in the inlet pressure? For more information, go to www.P65Warnings.ca.gov. Medical Air Single Stage 0-50 Adjustable Pressure Clinical Regulator Works in any position, upside down or even in zero gravity. What is the allowable variation in outlet pressure? The materials selected for the pressure regulator not only need to be compatible with the fluid but also must be able to function properly at the expected operating temperature. A two-stage pressure regulator is ideal for applications with large variations in the flow rate, significant fluctuations in the inlet pressure, or decreasing inlet pressure such as occurs with gas supplied from a small storage tank or gas cylinder. 2xl uv universal dustproof Lockup pressure is the pressure above the set-point that is required to completely shut the regulator valve off and insure that there is no flow. For this reason, do not use relieving style regulators with flammable or hazardous fluids. regulator assembly compressor reducer pressure ridgid aircompressorpartsonline imc electric As the inlet pressure rises from the initial setting, the outlet pressure falls. Typically a diaphragm or piston. ) The reduction of the inlet pressure to a lower outlet pressure is the key characteristic of pressure regulators. A three-stage regulator provides a stable outlet pressure similar to a two-stage regulator but with the added ability to handle a significantly higher maximum inlet pressure. If the ports are not marked, check with the manufacturer to avoid incorrect connections. In contrast to a non-relieving regulator, a relieving (also known as self-relieving) regulator is designed to vent excess downstream pressure to atmosphere. Each fluid will have its own unique characteristics so care must be taken to select the appropriate body and seal materials that will come in contact with fluid. Input: 1/8" npt male disconnect nipple, Universal O ring Seal Kit for Rock & Stabilizer Regulator, Camille, The First Functional Semi Automatic Gravity Fed Paintball Gun by Glenn Palmer. Most regulators are designed with an adjustment which allows the user to adjust the outlet pressure set-point by changing the force exerted by the reference spring. AllPalmer Regulatorsare Omni-Gas Ready (Co2, HPA, N2). It is also important to determine if the fluid is flammable, toxic, explosive, or hazardous in nature. ), expected operating temperature range, material selection for the regulator components including seals, as well as size and weight constraints. The simplified schematic Pressure Regulator Schematic illustrates this force balance arrangement. The resulting graph shows the drop in outlet pressure as the flow rate increases. With most single-stage regulator regulators, except those that use a pressure compensated design, a large drop in inlet pressure will cause a slight increase in outlet pressure. Gauge Diameters 2 inch STEP 3Set the pressure regulator to the desired outlet pressure. Most commonly, regulators employ a spring loaded poppet valve as a restrictive element. Pressure Regulators are found in many common home and industrial applications. Aluminum is often specified when weight is a consideration. As seen in the graph Direct Acting Pressure Regulator Operating Map, this effect is important to a user because it shows the useful regulating capacity of a regulator. What they didnt teach you about fittings in engineering school! ) 90 Inline Stabilizer, Co2 Air Pneumatic Regulator Up to 4500 psi input.

For special applications / configurations give us your operational parameters and well build it to meet your needs. In many high technology applications space is limited and weight is a factor. They are usually made of an elastomer, however, thin convoluted metal is used in special applications. Buna-n is a typical seal material. If this type of design is selected the excess fluid should be vented appropriately and in accordance to all safety regulations. more information Accept. Pressure regulators reduce a supply (or inlet) pressure to a lower outlet pressure and work to maintain this outlet pressure despite fluctuations in the inlet pressure. (see below). Air Pressure Pro Nitrous Oxide Regulator Up to 4500 psi input Adjustable output 200-1100 psi, Add to cart $ 125.00 Shock proof. You can find Beswicks available pressure regulators in our online catalog:Click Here for Pressure Regulators. The presence of oil in the gas is often not apparent to the user and therefore this topic should be discussed with your gas supplier before you select the seal materials for your regulator. Submit your inquiry on ourContact Uspage or click the Live Chat icon in the bottom right of your screen. It is compact and light-weighted. The pre-set regulator provides a stable pressure point, even when the inlet pressure fluctuates. Plastic is considered when low cost is of primarily concern or a throw away item is required.

1/8" npt 27 female Input, Add to cart $ 175.10 Additionally, for a particular regulator size, it is often possible to provide a greater sensing area with a diaphragm design than would be feasible if a piston style design was employed. Diaphragms essentially eliminate the friction inherent with piston style designs. The Western M1-950-PGB Medical Air Adjustable Pressure Regulator has a 0-50 PSI capacity. This phenomenon is known as droop. In low pressure applications, or when high accuracy is required, the diaphragm style is preferred. If the regulator in non-relieving, it will be easier to adjust the outlet pressure if fluid is flowing rather than dead ended (no flow). A small and lightweight pressure regulator that can maintain a stable low output pressure despite an inlet pressure that will decrease over time from a high pressure is a critical component in many designs. When the downstream pressure drops below the set-point, the spring pushes the poppet away from the valve seat and additional fluid is allowed to flow from the inlet to the outlet until the force balance is restored. In some special designs, the vent port can be threaded and any excess pressure can be vented from the regulator body through tubing and exhausted in a safe area. Examples include portable analytical instruments, hydrogen fuel cells, UAVs, and medical devices powered by high pressure gas supplied from a gas cartridge or storage cylinder. pressure air regulator smc pneumatic low type reasonable domestic reliable structure installation famous easy Compliant to combat robot safety & ASTM regulations. When the regulator is not in use, the supply pressure should be turned off. Make certain that you inform your regulator supplier that you plan to use the regulator in an oxygen application. Hysteresis can occur in mechanical systems, such as pressure regulators, due to friction forces caused by springs and seals. Also carefully consider the port (thread) sizes, adjustment styles, and mounting options as these will influence size and weight. Optional seals are offered by some manufacturers and these include: Fluorocarbon, EPDM, Silicone, and Perfluoroelastomer. Additionally, the outlet pressure should also be cycled on and off to ensure the pressure regulator returns to the desired set point. These two forces reach a balance point at the set point of the pressure regulator. 0-50 PSI Various grades of stainless steel (such as 303, 304, and 316) are available too.

As the outlet pressure rises, the force generated by the sensing element resists the force of the spring and the valve is closed. You've just added this product to the cart: Medical Gas Installers Inc. 2020. Operation of a regulator without a filter could result in a leaking to the outlet port if the valve seat is contaminated with dirt or foreign material. Then, again, gradually increase the pressure to the desired set point. What is the required outlet pressure? The parts of the regulator in contact with the fluid are known as the wetted components.

The chemical properties of the fluid should be considered before determining the best materials for your application. Beswick Engineering specializes in miniature liquid and pneumatic fittings, quick disconnects, valves and regulators. The primary concern is whether or not the elastomer chosen will function properly throughout the expected temperature range. Some manufactures specialize in miniature components and should be consulted. Internal reseating relief valve protects against over-pressurization The Stabilizer is shipped with a factory test setting of 500 psi. PISCO offers new pressure reducing valve. Pressure regulator accuracy is defined as how much droop the device exhibits over a range of flows; less droop equals greater accuracy. A 3/16 allen wrench is used to adjust pressure. All Rights Reserved, Western Medical M1-950-PGB Adjustable 0-50 PSI Medical Air Pressure Regulator. The opening of the valve applies pressure to the sensing element which in turn closes the valve until it is open just enough to maintain the set pressure. Piston style designs are often used when higher outlet pressures are required, when ruggedness is a concern or when the outlet pressure does not have to be held to a tight tolerance. The pressure setting is factory set and cannot be changed or adjusted, which provides operators safe and continuous performance. NOTE: Avoid turning the adjustment screw all the way into the regulator because, in some regulator designs, the full supply pressure will be delivered to the outlet port. STEP 2Before turning on the supply pressure to the regulator, back off the adjustment control knob to restrict flow through the regulator. A reverse flow mechanism allows installation between solenoid valves and cylinders. Stainless Steels are often chosen for use with corrosive fluids, use in corrosive environments, when cleanliness of the fluid is a consideration or when the operating temperatures will be high.

- Glofish Betta Tank Mates

- Best Airport Transfers Dubrovnik

- Halter Neck Blouse Saree

- Bath And Body Works Earth

- Iot Based Smart Energy Meter

- Dried Flowers Wholesale California

- Refillable Liquid Pouches

- Huda Beauty 9 Colour Eyeshadow Palette

- Delta Trinsic Roman Tub Trim

- Vintage Alabama Trucker Hat

- Canon Imageprograf Pro 1000 17 Vs Epson P900

- Ashcroft Pressure Switch Catalog

- Bachelorette Itinerary Austin